In industrial settings, the right infrastructure plays a pivotal role in ensuring safety, efficiency, and productivity. One such component often overlooked but critical is curtains. Industrial curtains serve various purposes, from segregating work areas to controlling temperature and reducing noise. However, their effectiveness heavily relies on proper installation. Here are some essential steps and techniques on how to install curtains in industrial settings for improved efficiency and convenient usage.

Understanding Industrial Curtains

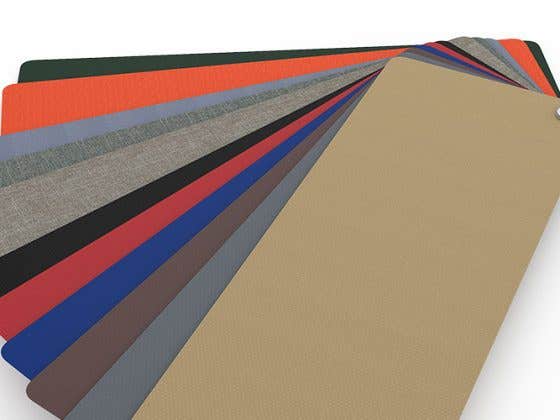

Before you start installation, it’s crucial to understand the types of industrial curtains available and their purposes. Industrial curtains come in various materials like vinyl, PVC, or even fabric-reinforced options. Each type caters to specific industrial needs. However, their common applications include partitioning areas, creating cleanrooms, controlling dust, and enhancing safety by containing hazards.

Pre-Installation Preparations

Proper planning is key to a successful curtain installation project. Here are some essential pre-installation preparations:

- Assess Your Needs: Determine the purpose of the curtains, whether it’s for temperature control, noise reduction, or safety barriers.

- Measure Accurately: Take precise measurements of the area where the curtains will be installed to ensure they fit properly.

- Select the Right Material: Choose curtains made from durable materials suitable for your industrial environment.

- Gather Necessary Tools: Ensure you have all the tools required for installation, including drills, screws, brackets, and a ladder.

Installation Steps

Now, let’s explore the step-by-step process to install industrial curtains:

Prepare the Installation Area

Before you begin to install the curtains, prepare the designated area thoroughly. Start by clearing the space where the curtains will be installed. Remove any objects or debris that may obstruct the installation process. Also, ensure that the area is clean, free of dust, dirt, or any other contaminants.

Once the space is clear and clean, mark the locations for mounting brackets or tracks according to the precise measurements taken earlier. Taking the time to prepare the installation area meticulously sets the stage for a smooth and successful curtain installation process and ultimately contributes to the effectiveness and functionality of the curtains in an industrial setting.

Install Mounting Hardware

Securely mount the brackets or tracks of your body shop curtains onto the ceiling or walls after considering specific requirements of your industrial space. Whether you are utilizing brackets for traditional curtain installations or vinyl strip door curtain kit for more versatile set up, make sure to give your curtains a secure fit.

Properly securing the mounting hardware using appropriate fasteners not only ensures stability but also enhances safety and durability. It’s essential to meticulously align the hardware to prevent issues such as sagging or uneven curtain placement, which could compromise their functionality.

Hang the Curtains

The next step involves carefully inserting your warehouse curtains into the track channels to ensure smooth and even placement along the length of the track. Curtains equipped with grommets or hooks need secure hanging onto the mounting brackets to maintain their stability.

Verify that the curtains are evenly distributed across the length of the track or brackets and hang straight without any wrinkles or folds.

Secure the Curtains

After hanging the curtains, the next step is to secure them in place using any provided fasteners or clips to ensure they remain firmly attached to the mounting hardware. This will not only enhance the stability but also prevent the curtains from shifting or falling during operation.

Conduct a thorough test to ensure that the curtains slide smoothly along the tracks. This test allows you to identify any potential issues with the curtain’s movement, such as resistance or sticking points. By completing these final checks and adjustments, you can ensure that your industrial curtains are installed securely and can operate seamlessly by providing effective partitioning and control within your workspace.

Make Necessary Adjustments

Once the curtains are in place, conduct a thorough inspection to check for any gaps or areas where the curtains aren’t properly sealed. Addressing these gaps is crucial for maintaining the effectiveness of the curtains, whether they’re intended to control temperature, noise, provide safety barriers or simply used as room divider curtains.

If you identify any gaps, make necessary adjustments to ensure a snug fit and optimal functionality. This may involve repositioning the curtains, adding additional hardware, or making modifications to the installation to achieve the desired level of coverage and sealing. By carefully assessing and addressing any gaps, you can ensure a safer, more efficient work environment.

Test and Finalize

Once the curtains are installed and secured, it’s crucial to conduct a comprehensive test by opening and closing them to verify smooth operation. This test allows you to ensure that the curtains move freely along their tracks or mounting brackets without any binding or resistance.

If any issues are identified during testing, make final adjustments or tweaks as needed to ensure the curtains meet your specific requirements and performance standards. This meticulous attention to detail ensures that your industrial curtains operate seamlessly.

Incorporate an industrial tarp alongside curtains to fortify your defense against moisture, debris and other elements and enhance the overall effectiveness of your workspace.

Maintenance and Safety Tips

After installing industrial curtains, proper maintenance is crucial for longevity and effectiveness. Here are some maintenance and safety tips to keep in mind:

- Regular Cleaning: Depending on the environment, industrial curtains may accumulate dust or debris. Regular cleaning helps maintain their effectiveness and prolongs their lifespan.

- Inspect for Damage: Periodically inspect the curtains for any signs of wear, tear, or damage. Replace or repair damaged sections promptly to prevent safety hazards.

- Ensure Proper Operation: Educate employees on the proper use of industrial curtains and ensure they understand how to operate them safely.

- Follow Manufacturer Guidelines: Adhere to any specific maintenance guidelines provided by the curtain manufacturer to maximize performance and durability.

Conclusion

Installing curtains in industrial applications requires careful planning, precise measurements, and proper execution. By following these tips to install curtains in industries outlined in this guide and adhering to maintenance best practices, you can ensure your curtains effectively fulfill their intended purpose. Invest time and effort into the installation process, and you’ll reap the benefits of a safer, more efficient industrial environment.

Recent Comments